ABOUT US

Welcome to Supertech Engineers

We are manufacturer of Sewer Suction Machine

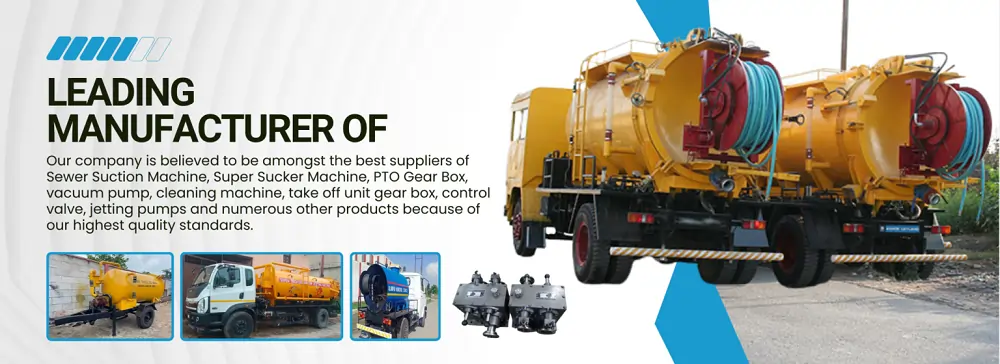

Our company is believed to be amongst the best suppliers of sewer suction machine, super sucker machine, pto gearbox, vacuum pump, cleaning machine, take off unit gear box, control valve, jetting pumps and numerous other products because of our highest quality standards. Our offerings are quality based because we make them with fine raw materials and advanced technologies. Every creation in our portfolio delivers maximum profit to users by working flawlessly. Vacuum Pump, Cleaning Machine, Take Off Unit Gear Box, Control Valve, Jetting Pumps and much more.

- Innovative Technology

- High-Quality Manufacturing

- Exceptional Customer Support

- Competitive Pricing

- Proven Track Record

- Custom Solutions

We’re in this business Since 2012 and we provide the best services

Our Products

What makes us best in this industry?

We “Super Tech Engineers” have gained success in the market by Manufacturing a remarkable gamut of Vacuum Pump, Cleaning Machine, Take Off Unit Gear Box, Control Valve, Jetting Pumps and much more. We are a well-known and reliable company that is incorporated in the year 2012 at Ghaziabad (Uttar Pradesh), India.

Send us a Message